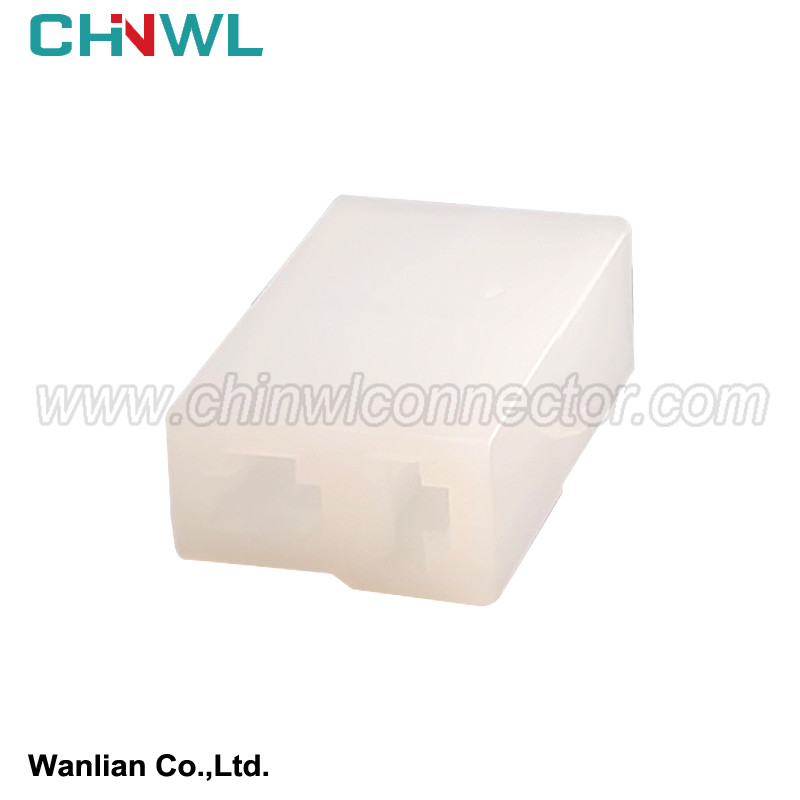

Wanlian #: WL029CD2-6.3-21

Mfr. #:

Mating #: WL029CD2-6.3-11

Accessories: Terminal Seal

|

Wanlian part number: |

|

WL029CD2-6.3-21 |

|

Original number: |

|

|

|

Gender: |

|

Female |

|

Specification: |

|

Housing: PBT+G; PA66+GF; PA66; PBT; Nylon |

|

Type: |

|

Connector |

|

TUV, TS16949, ISO14001, ISO 9001, RoHS conform: |

|

Yes |

|

MOQ: |

|

No minimum order quantity |

|

Supply sample: |

|

Yes |

|

Customized drawing with Decal, Frosted, Print are available as request |

|

Yes |

|

Payment method: |

|

We accept Paypal, TT, Alipay, West Union etc. |

|

Transportation method: |

|

Air Transport: UPS, DHL, FEDEX etc; Sea Transport; Railway Transport; Freight Forwarding etc. |

|

Production Capacity: |

|

1000000pieces/Month |

In the use case, it is recommended that after the wiring harness is assembled, the connector terminal itself is not stressed. Only when the overall wiring harness is subjected to vibration, impact and relative displacement with the vehicle body due to the operation of the car, the purpose of strain relief is achieved through the flexibility of the wiring harness, even if a small amount of strain is transmitted to the connection. Connector terminals, the stress does not exceed the design retention force of the terminal in the connector.

The automotive wire harness connector is used to connect the connection points of the automotive circuit. It is an important part of the car, and its quality directly affects the transmission effect of power or signals. Connectors account for a small proportion of the cost of automobiles, but if there are quality problems in the use of automobiles, there will often be serious consequences, and the maintenance cost will increase significantly. Therefore, the quality of connectors is increasingly recognized by automobile manufacturers and attention of component suppliers.

Terminal withdrawal is a relatively common failure form of automotive wire harness connectors. It means that after the connector is assembled, the terminal and the sheath are separated abnormally, resulting in the loss of the function of the connector. The causes of this failure form generally include three aspects: ① The holding force of the terminal in the sheath is unqualified; ② Interference with the insertion; ③ Product application problems. According to the reasons of these three aspects, this article analyzes and proposes solutions to the connector terminal withdrawal

Unacceptable retention of the terminal in the housing

The retention force of the terminal in the housing is the force required to axially separate the terminal from the housing. In order to avoid the phenomenon of terminal pin withdrawal, the performance test standard of the connector has strict regulations on the retention force of the terminal in the sheath: ①The retention force of the connector with a specification not greater than 2.8 is greater than 40N; ②The connector with a specification greater than 2.8 The connector holding force is greater than 60N. In practice, most of the phenomenon of terminal withdrawal occurs because the retention force does not meet the requirements. Generally speaking, the reasons for the unqualified holding force of the terminal in the sheath are: structural design problems; material selection problems.

Simple instructions:

We have product Catalogue,please contact us on skype,WhatsApp or Email.

If you can't find a product on our website or catalog, We deal with over 10,000 items, our catalog doesn’t cover all products. And we are developing 100+ molds yearly, which means around 10 new products are created in our factory. So don’t go away, just send us your photo or part no, we’ll check for you.