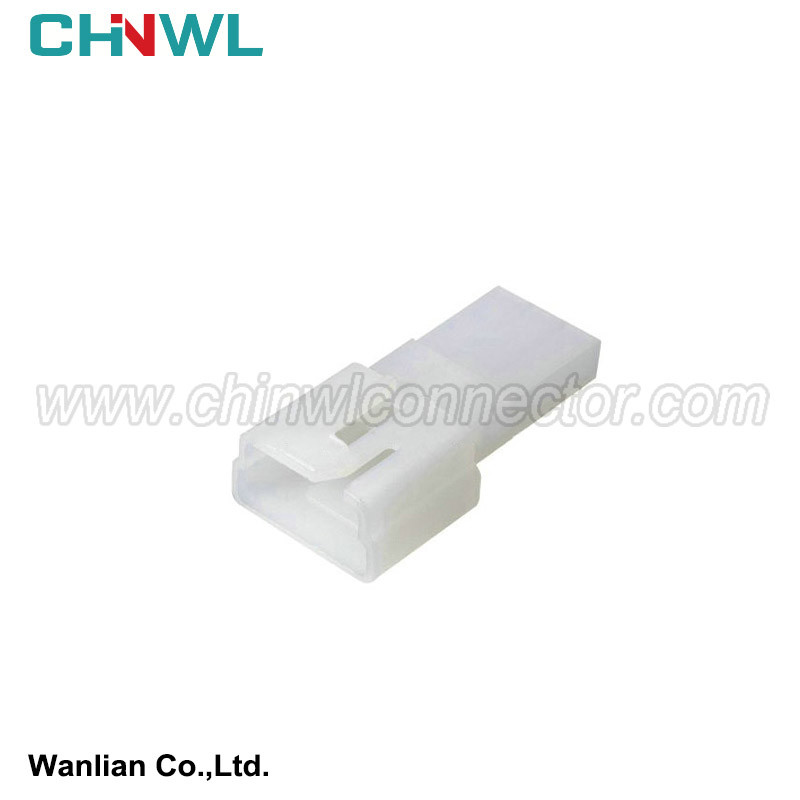

Wanlian #: 7123-1430

Mfr. #: 7123-1430

|

Wanlian part number: |

|

7123-1430 |

|

Original number: |

|

7123-1430 |

|

Gender: |

|

Male |

|

Specification: |

|

Housing: PBT+G; PA66+GF; PA66; PBT; Nylon |

|

Type: |

|

Connector |

|

TUV, TS16949, ISO14001, ISO 9001, RoHS conform: |

|

Yes |

|

MOQ: |

|

No minimum order quantity |

|

Supply sample: |

|

Yes |

|

Customized drawing with Decal, Frosted, Print are available as request |

|

Yes |

|

Payment method: |

|

We accept Paypal, TT, Alipay, West Union etc. |

|

Transportation method: |

|

Air Transport: UPS, DHL, FEDEX etc; Sea Transport; Railway Transport; Freight Forwarding etc. |

|

Production Capacity: |

|

1000000pieces/Month |

2. Draw a three -dimensional wiring diagram

Although the wiring diagram reflects the actual installation location of the electrical equipment on the car, the wires on the map are criss -horizontal, which increases the difficulty of reading the picture. In order to make the circuit diagram closer to reality, drawing the beam installation diagram often needs to be drawn. The wiring beam installation chart sets the wires in the wiring diagram relatively concentrated to form a wiring beam.

In the car, in order to install the convenience and protective wires, the cotton veil or polyvinyl chloride plastic band is commonly used to bandage many wires on the same road, called the wiring beam.

Pay attention to the following questions when drawing a three -dimensional wiring diagram:

① According to the different positions of each electrical component, the form of three -dimensional wiring is determined. At present, the internationally common wiring form is generally E and H.

② Simulate the diameter of the cable beam in different areas.

③ Consider the sealing and protection of the thread beam over hole.

④ Determine the fixed hole position and fixing form of the wire beam.

⑤ Theoretically, it is the most reasonable to connect all electrical devices to connect a wire beam, but it is difficult to do when it is actually loaded, so the wire beam should be reasonably separated. In the case of convenient assembly, try to use systematic design.

⑥ The design of the iron point design is very important in the design of the line beam. Improper design can cause signal interference and affect the realization of certain electrical functions. It should be designed as multiple iron points according to different models. The design of the iron should meet the following points:

a. Weak signal sensor should be carried out alone and nearby to ensure the normal transmission of the signal.

b. ECUs should be carried out separately to prevent interference.

c. The battery's negative electrode iron, engine, transmission, and iron should be carefully considered.

Simple instructions:

We have product Catalogue,please contact us on skype,WhatsApp or Email.

If you can't find a product on our website or catalog, We deal with over 10,000 items, our catalog doesn’t cover all products. And we are developing 100+ molds yearly, which means around 10 new products are created in our factory. So don’t go away, just send us your photo or part no, we’ll check for you.